Courtesy of Pool Pak

Pools make for challenging construction in outside installations, but they become increasingly complex as you bring them indoors. You not only have to be concerned about the pool system, you now have to address issues like dehumidification, water and space temperatures and higher operating costs. “Inside knowledge” can go a long way in facility construction and dehumidification equipment choices.

The main issue is, of course, what to do with the water vapor that forms over a pool in an enclosed space. As moisture fills the structure, damage can occur and in general the environment becomes uncomfortable for occupants. Before the advent of modern dehumidification systems, doors and windows were left open, providing minor relief from the humidity. Fans were later added to help draw out moisture and maintain a balance, but this method also proved only marginally effective, especially in colder climates where heating was required.

Today’s dehumidification systems have come a long way since then and are designed specifically for the corrosive indoor pool setting. They not only manage moisture, they recycle energy, maintain tight temperature setpoints and can offer instant performance and maintenance details from any location with access to the internet. It’s important, however, to understand the indoor environment and how dehumidification equipment functions to get the best performance from your system.

Factors In Harmony

There is an ongoing relationship between internal and external temperatures, humidity level, structure type, ventilation, pool water chemistry and equipment. When all are working in harmony, the facility will provide a comfortable, healthy environment that is cost effective to operate. When the variables begin to change, comfort, operating cost and/or maintenance can suffer greatly.

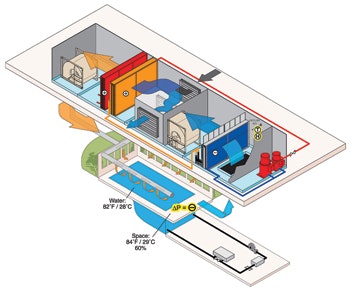

Water/air temperatures and humidity levels must be within a narrow range for occupant comfort. Ideal water temperature is around 82 degrees with the air temperature slightly higher to prevent chilling once exiting the pool. The desirable humidity range is generally 50 percent to 60 percent. Anything greater than 60 percent creates a sticky feeling and/or difficult breathing, and low humidity results in evaporative cooling on the bather’s skin, resulting in a chill. Athletic pools hosting swim meets generally operate with cooler water/air temperatures and health/therapy facilities tend to have higher water/air temperatures.

The poolroom environment is in a constant state of flux as internal and external variables change from season to season. Outside temperatures affect the inside heat loss/gain sometimes, resulting in the need for more energy to maintain occupant comfort. For a majority of indoor pools, regardless of geographic location, water and space heating are required 70 percent to 90 percent of the year.

Indoor pool designers and contractors need to control and balance five crucial variables that include indoor air quality (IAQ), occupant comfort, energy cost, pool water chemistry and asset protection. The interrelationship between the variables is complex, and changing one or more may affect the others. Small variations in the pool environment may result in discomfort; large imbalances in the pool environment can result in very high operating cost, destruction of equipment and structure and even occupant injury.

Evaporation Control

Management of the rate of evaporation is an important aspect of indoor pool environment care. At a base level, it is a function of water temperature — the higher the water temperature, the greater the evaporation rate. That evaporation rate is also influenced by the difference in temperature between the water and air, and the greater the difference between the warm water and the cooler air above it, the greater the rate.

The rate of evaporation is also a function of the water surface area, a concept that also applies to the tremendous increases in water surface area due to agitation from pool activity, water slides and implements such as water cannons. The splashing water increases the effective surface area thereby increasing the evaporation rate within the pool structure.

Another important fact to keep in mind in this discussion is evaporation removes heat from the water, which causes it to cool. To maintain water comfort conditions, additional energy is needed to overcome evaporative heat loss and sustain the water’s original set points.

So where does all this evaporated water — this moist air — go? If not removed through ventilation or mechanical dehumidification, it will condense on any cold surface it touches. In most cases, this condensate includes chloramines, a corrosive byproduct of the pool’s sanitization process, that aggressively attack metallic surfaces including furniture, fixtures and structural components.

There are confirmed incidents where corrosive moisture has leached into precast concrete roof structures, corroding the rebar, resulting in collapse and injury. A little known fact is that chloramines in the saturated air also attack and discolor most common stainless steels creating “stress corrosion,” which can lead to structural failure. That’s why it’s critical to constantly maintain correct pool chemistry — keeping chloramines under control — along with the proper relative humidity.

The Pool-Spa Operator’s Handbook recommends chloramine levels not exceed 0.2 ppm. Above that level, the corrosion process caused by the chloramines in the air accelerates. It’s important to note that chlorine odor is often blamed on poorly functioning dehumidification units but in reality is the result of improper pool chemistry. Dehumidification equipment can help dilute the odor through ventilation but will not fix the problem. High levels of chloramines over prolonged periods will not only affect the pool facility (not to mention bathers), but it can also cause severe damage to the dehumidification unit.

Courtesy of Pool Pak

Dehumidification Systems and How They Work

For ease of discussion, dehumidification systems can be divided into two major types: those using mechanical refrigeration to remove moisture and ventilation-based systems using dryer outside air and having no refrigeration components. There are advantages and disadvantages to each system, and your choice will depend on initial cost, operating cost, maintenance, level of desired control and location.

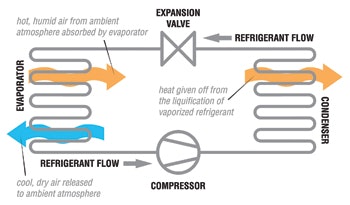

Pool dehumidification systems using mechanical refrigeration, often referred to as Direct Expansion (DX) systems, are the most popular. They are probably the most common dehumidification systems used for small to medium pool room applications due to their tight control of the space temperature as well as overall good life cycle cost. Heat and moisture are removed the same way an air conditioning system does it, with the major difference being the way the system reuses the recovered heat.

In all DX systems, refrigerant vapor flows through the compressor, raising its temperature and pressure. The refrigerant then flows through the condenser, where it condenses to a liquid, giving off heat in the process. The refrigerant next goes through the expansion valve, where it experiences a pressure drop before going to the evaporator, where it absorbs heat, causing the refrigerant to vaporize again and in this state it returns to the start of the cycle. This last phase, where heat energy is drawn from the surrounding air, is the desired effect and the part we’re paying for. As this happens — as the warm, moist pool air flows over the cold evaporator coil, moisture condenses and drains away while the air is cooled.

In a conventional air conditioning system, the heat generated during the compression cycle is normally discharged to the surrounding outdoor environment. Dehumidification systems for pools, however, are designed as heat pumps, using the waste energy to heat the pool water and/or air. The recycled energy in many cases can satisfy up to 90 percent of the pool’s heating requirements A process called hot gas reheat is used to reclaim the heat energy, and that simply means the heat removed from the warm, moist air as it enters the dehumidifier is added back to the air as it passes through the unit. The result is the warm, moist is converted into warm dry air as it leaves the dehumidifier and returned back to the pool to start the cycle again. The moisture is likewise removed during the air cooling process in the form of condensation.

The benefit of this approach is the high Coefficient of Performance (COP). Efficient dehumidifiers have a COP around 5, which simply means five units of “heat energy” is produced for every unit of electricity used. This heat energy is then used to heat space or the pool water.

Packaged dehumidification equipment built for pools incorporates more sophisticated mechanical design and software than conventional air handling systems, and this helps to minimize operating cost. Initial cost for these systems is higher than ventilation systems because of the added refrigeration components, but the cost of operation decreases over time because less supplemental heating energy is needed. They do require periodic HVAC maintenance and a certain level of knowledge to operate, but the added benefits can easily outweigh the extra cost.

DX dehumidification systems offer very precise facility temperature and humidity control during all seasons for maximum occupant comfort. They will operate in any geographic area, including the hot, moist Southeast and can offer cooling by adding an outdoor condenser.

Using Outside Air for Moisture Control

Dehumidification can also be effectively managed using ventilation to remove excess moisture. This is accomplished through dilution with outside air, and is a brute force approach to dehumidification under the premise that enough drier, outside air will offset the effects of pool evaporation. This system has no self-contained means of cooling during the hot summer season, especially when the temperature difference between outside and inside is minimal, although a chilled water coil can be incorporated from an external system.

Packaged outside air systems can be equipped with a furnace to maintain air and water temperatures or they can rely on external auxiliary heaters. For energy efficiency, using an air-to-air heat exchanger in the supply and exhaust air steams can reduce fossil fuel heating by up to 50 percent.

Capital cost is lower for a packaged ventilation system compared to mechanical refrigeration systems, and the technology requires less technical personnel for maintenance. Temperature and humidity control are not very good with a ±30 percent variation during the summer season.

Dehumidifiers that use mechanical refrigeration also use outside air to remove moisture, but to a much lesser degree. Ventilation is required to meet IAQ requirements, and compressors can be shut down during non-peak hours and evenings when outside conditions permit to save on energy usage.

Courtesy of Pool Pak

Good Facility Construction Practices Increase Efficiency

Choosing the right dehumidifier for your pool is only part of the equation when designing an efficient indoor pool enclosure. Approved construction techniques save energy, reduce condensation and improve comfort.

The objective of an air distribution system within a high moisture environment is to maximize flow of warm, dry supply air over any surface that is prone to condensing temperatures, including all walls, windows and skylights.

A ceiling supply arrangement should be located near the windows, preferably close enough to sufficiently wash the cold glass with an even blanket of air. Up to 80 percent of the supply air should be directed at the walls and windows. Washing the walls with warm, dry air reduces the incidence of cool, dead air spaces that may form around windows or walls and migrate to the pools edge.

The remaining 20 percent of the supply air should be directed along the ceiling to break up any stratification and stagnation occurring near the ceiling. For low-set windows and sliding glass doors, the supply air should be ducted below grade around the inside perimeter of the enclosure using corrosion-resistant PVC piping and linear slot diffusers.

Return inlets should be located to allow efficient flow of the moist, warm air back to the dehumidification unit. This not only increases dehumidification efficiency, it also eliminates dead areas where air stagnation can occur.

Traditionally, return duct heights have been about 10 to 15 feet above the floor, but it has been found that chloramine-saturated air blankets the pool surface and does not adequately re-circulate through the dehumidification system. The result is poor indoor air quality that poses a health risk for the pool occupants. A better strategy is to position return(s) near the surface to lightly draw off the chloramine layer and moist air while not dramatically altering the evaporation rate or creating uncomfortable air currents.

Return and supply ducts should never be positioned as to allow short cycling of the supply air. Short cycling occurs when supply air is released too close to the return duct causing it to prematurely return to the dehumidifier before it is able to circulate in the space.

Another important consideration is to maintain negative air pressure in the pool area relative to the surrounding spaces within the same building. The negative pressure prevents both moisture and chlorine odors from drifting into other areas of the building.

Moisture Barriers Prevent Moisture Migration

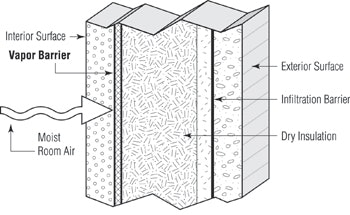

Moisture migrates from a space with a high humidity ratio to a space that has a lower humidity ratio. It migrates through most building materials, and can cause condensation on building surfaces and leach into concrete walls.

As moisture migrates through walls, it will impregnate the insulation and condense as the outside temperature drops and the dew point is reached. This will result in a decrease in R-value from the wet insulation and even a loss of structural integrity.

At the very least, vapor barriers should be installed immediately behind the interior wall surface facing outside, but a more comprehensive approach is to protect all natatorium walls, ceiling and flooring to totally isolate the moisture.

In addition to the inside walls, exterior walls of the natatorium must be built so infiltration of outside air will be blocked near the outside surfaces of the enclosed space. A vapor membrane at a warm-wet inside surface blocks infiltration, but local condensation will occur if cold infiltrating outside air contacts this boundary. Vapor membranes and infiltration barriers must be completely sealed or condensation can occur at or near leakage points.

Good thermal performance doors and windows exposed to outside air limit heat migration and condensation formation. Double and triple glass panels are best and they should be insulated or sealed in metal or vinyl clad frames wherever possible. Window frames must have thermal breaks and be sealed to adjacent walls and insulated with a non-porous insulating material.

Building and maintaining an indoor pool facility is a major undertaking, and it must operate efficiently to maximize the return on investment. By selecting a packaged dehumidification system designed for your unique location, you can be assured of maximizing user comfort, protecting assets and reducing maintenance to the lowest possible cost.

Marcy Glatfelter, inside sales manager at PoolPak International, has been in the HVAC/R industry for more than 12 years. Prior to her promotion to Inside Sales Manager, she held the position as Inside Sales and Application Engineer since her start with the company in 2007. She can be reached at [email protected].

Comments or thoughts on this article? Please e-mail [email protected].