Even the most ardent proponents of automatic pool covers will admit that the technology hasn’t seen significant innovation over the past several years. That looks to change in the near future when an entirely new concept in auto covers comes to the market.

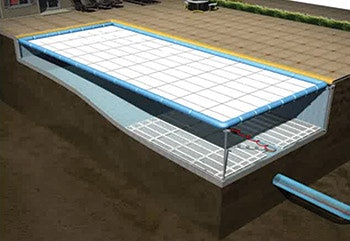

It’s called Floatek, an invention from Ami Kolechstein of Vancouver, Canada. The concept is based on the use of inflatable, interlocking tiles that fit together to form a cover that provides both the safety and energy savings typical of traditional automatic pool covers.

It’s an elegantly simple concept that uses buoyancy and gravity rather than hydraulics or electric motors to deploy and retract the cover. When the pool is open, the cover rests on the floor of the pool. When it’s time to cover the pool, the tiles are filled with a very small amount of air, just enough so they become buoyant and float up like a submarine coming to the surface. Once on the surface, a flexible pontoon around the perimeter of the cover inflates to lock it into place. Then, when users are ready to open the pool, the air is removed, allowing the cover to sink back to the bottom.

Kolechstein was prompted to invent the system as a result of a proposal he made to Vancouver’s Park Management Board to transform an outdoor swimming pool at the city’s Stanley Park into a 30,000-square-foot public “hot spa,” an idea based on a European trend toward hotwater pools. Although city officials liked the idea, the project hit a big snag due to the cost of heating the water. Researching cover options with mechanical engineers and pool cover companies, Kolechstein discovered there were no automatic covers available anywhere in the world that were large enough to cover the pool.

That was when he decided to develop a cover system that could be used on any size pool, yet remain affordable and easy to install on existing pool structures. Kolechstein shared his idea with the Stanley Park pool manager, who encouraged him to pursue the innovation, noting an ample market for such a product.

“Installing an automatic cover on an existing pool is an expensive process,” he says. “That’s left homeowners and commercial pool managers with bubble thermal covers, which are inconvenient to use and provide no safety. Floatek can not only be made to fit pools of any size or shape, new or existing, but it can provide a return on investment within approximately three years. It functions both as a safety cover and insulator to dramatically reduce heat loss due to evaporation.”

The system is operated using a combination air-compressor/vacuum unit installed at the equipment pad to inflate and deflate the tiles. Air is delivered to the cover via a quarter inch tube run through the main-drain plumbing. Metal guide poles are installed in the pool to control the cover as it moves up and down.

Kolechstein is currently seeking NSF and ASTM compliance certification, which he anticipates securing in the next few months with production beginning in 2015.

Learn more about the cover in the video below: