All photos courtesy Kevin Misley

All photos courtesy Kevin Misley

Editor's Note: This story first appeared in The Edge, member publication of the Northeast Spa and Pool Association.

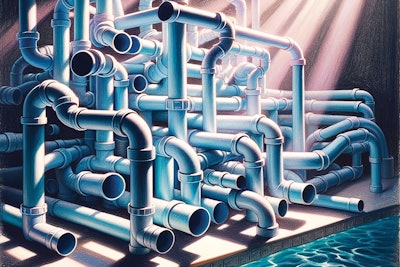

It has been said many times that the circulation system is the heart of a pool or spa.

Installing and maintaining pool plumbing systems requires a thorough understanding of plumbing principles. Technicians must know how to correctly connect pipes, fittings and valves to ensure proper water flow, circulation and pressure. They must also be able to identify and address potential issues before they lead to significant breakdowns.

Grasping the fundamental plumbing concepts enables technicians to identify the source of problems and implement effective solutions. For those with experience, this article will be a reminder of best practices. For newer hires, it's a great starting point toward proper habits.

THE STARTING POINT

It starts by performing the proper calculations to match pump size with piping size. With that knowledge, you can establish a material list for your project. The list should include, but not be limited to, digging tools, pipe cutting tools, pipe bending tools, tape measures, levels and solvent cements.

The predominant pipe used in pool and spa applications will be Sch 40 rigid PVC or Sch 80 PVC pipe. In some cases, CPVC pipe or fittings will be used. Both Sch 40 and Sch 80 fittings are interchangeable; the only difference between them is the inside diameter. Sch 80 has a smaller ID and is a thicker pipe than Sch 40. Sch 40 pipe is white in color, and Sch 80 is gray. Be aware that the electrical conduit is also gray and should not be confused with the Sch 80 water pipe.

Identifying and using fittings specifically used for pressure applications is paramount for pool and spa projects and water features such as fountains or waterfalls. The use of DWV (drain water vent) fittings is unacceptable. DWV is for non-pressure plumbing applications only.

Many valves are used, but the most common are CPVC diverter-type valves. They can be equipped with motorized valve actuators for remote operation. Butterfly valves are commonly used in large commercial applications. Ball valves and gate valves are other types.

Using the proper solvent cements is essential, as certain cements have pipe size limitations. It's important to read the labels and understand the differences. Always use a PVC primer as it cleans and softens the pipe and fittings by creating a chemical reaction to allow PVC cement to bond properly. This active ingredient is called tetrahydrofuran.

PVC cleaners are available to remove grease or oils from pipe and fitting surfaces.

JOBSITE ESSENTIALS

Now that you have your list, you are ready to head to the jobsite armed with all your tools and a working plan for your plumbing runs.

Upon arrival and review, you might find some obstacles that can derail your perfectly drawn pipe plans: buried gas and electric lines, sewer lines, septic lines, trees, tree roots, a storage shed or a pool house.

Now, you must pivot and think outside the box for your pipe runs. This may include additional fittings or some tricky pipe bending to go around obstacles. It may increase your pipe run, requiring you to revisit your hydraulic calculations to ensure your change will not affect the proposed performance.

Utility markouts are required by law but only cover utilities and other buried services in the front of the property. Locating any of these items in the rear of the property, where you generally work, is your or your company's responsibility.

I prefer to locate and pour a large concrete equipment pad and arrange and assemble the equipment before the pipe runs. A large pad allows for ease of future servicing.

Begin your trench excavation and maintain a standard depth for your piping. Generally, we dig 2 feet plus to allow room for contractors coming in after for such things as plants and irrigation lines.

A bed of sand around 4 feet allows you to level uneven sections and protects the piping. You can begin assembling your piping and head toward the equipment set. The ends of your pipe cuts must have a bevel of between 10 and 22.5 degrees. This is the ASTM standard (D2855-20 section 7.2 and 7.3).

The purpose of the bevel is to ensure the pipe slides into a fitting easily and also allows proper solvent cement coverage on the pipe and the fitting during assembly. Leaving the sharp end on your pipe cut may cause the cement to be "snowplowed" toward the fitting, resulting in adequate coverage on the pipe. There are several manual beveling tools for certain pipe sizes.

For buried pipe, we always use colored glue for a quick visual inspection. Our equipment sets always use a clear primer and glue for a neat, clean finish. Covering equipment with cardboard and rags prevents glue drips on the pad and the equipment. Always wipe glue joints with a rag.

THE FINAL TOUCHES

Once you have completed all your connections, you must pressure test for integrity. The IPC/ISPSC (specifically section 311.9 in the ISPSC) requires a hydrostatic pressure test (use of water) of 25 psi for 15 minutes. Per section 302.7, using compressed air on plastic pipe is prohibited. Test plugs designed for water pressure testing must be used. Tapered winter plugs will not hold. Threaded plugs or PVC caps are another choice.

Evacuate all water from the lines; it may be weeks or months before fresh water is run through. Also, pressure testing when cold temps are creeping in may pose a problem with freezing.

Backfilling your piping with clean material prevents damage. We often use sand to cover pipes at least 8 feet and top off with the spoils from excavation, removing any rocks as we go. Though the excavated material is sometimes unsuitable, we will truck in clean material.

Now that your equipment and pipe are in place, the next step is to label your pipes at your equipment set. Hopefully, you have identified your pipes as they were set in the trenches. There are few label makers on the market that allow for custom identification. Use labels that are specific for outdoor applications. Don't use a Sharpie! Labeling equipment allows your customers to easily identify an equipment problem in case of a frantic phone call.

Be neat, clean and professional. Make your equipment sets a thing of beauty, and you can be proud of what you've accomplished.

Kevin Misley, president of Mystic Pools, has been involved in the swimming industry since 1983. He started his company in 1986 in the service sector. Over the years, the company has incorporated renovations and new construction.