Swimming pool and spa renovation is a substantial market for pool builders but renovating some older pool and spa systems can offer major challenges. While going through the planning stages of the renovation, you may discover that the existing pool and spa has undersized piping and pool equipment, making it difficult to achieve the turnover flow rates necessary to maintain proper water quality.

Additionally, you may find that the regulations regarding drain safety must also be addressed as many existing pools were not constructed to meet the requirements of the VGB Pool and Spa Safety Act (VGBA), the federal drain cover law APSP-16, Standard for suction outlet fitting assemblies (SOFA), or PHTA-7 Standard for suction entrapment avoidance. This article covers critical equipment and piping upgrades that should be addressed during a renovation to ensure water quality and safety.

TWO MAIN PROBLEMS:

1. EXISTING POOL EQUIPMENT

Pools constructed in prior years may not comply with present day building standards, codes, efficiency requirements and federal law. Serious consideration of this fact must be given when renovating existing pools.

2. EXISTING PIPING AND FITTINGS

Older swimming pools may have been built with piping systems that are undersized. In past years, water velocity and safety were not adequately considered when those pools were designed and built. When the APSP-7 Standard was introduced in 2006 (now ANSI/PHTA/ICC-7 2020), it required many changes to the way suction piping in pools and spas was to be installed. The requirement to have multiple suction outlets had a major effect on improving safety. Many existing pools and spas were built using only one small, blockable suction outlet cover. Prior to 2006, this was very common. It is now known that these pools and spas pose serious safety issues due to suction entrapment. The 2007 VGB Act addressed these issues for public pools; however, many existing residential pools still do not meet those requirements or the PHTA-7 standard. When renovating an existing pool or spa, one must address this common issue to ensure safety when the work is complete.

MAIN ELEMENTS TO CONSIDER

1. PUMPS AND FILTERS

Properly sized pumps and filters are critical to proper sanitation and water quality. To achieve an adequate turnover rate, the filtration pump and filter must be sized accordingly to have the capacity to handle the necessary turnover flow rate. In addition to a properly sized pump and filter, the piping system must also be sized accordingly to handle the water flow and velocity requirements of modern, code compliant pool design. Older pools may not have a filtration system or piping sized large enough to handle the flow and turnover rates necessary to maintain water quality and entrapment safety.

2. TURNOVER RATES

The current requirements for turnover rates are 12 hours for residential pools, six hours for public pools and 30 minutes for spas. Using the total volume of water contained in the pool, and calculating the Total Dynamic Head (TDH), planning to install correctly sized pumps and filters to provide the necessary flow and turnover rate should be considered to ensure water quality and sanitation. TDH is the sum of the difference in elevation between the source and destination and the friction losses in a piping system.

3. EXISTING PIPING ALWAYS PROVES TO BE THE CHALLENGE

Existing residential pools and spas often have undersized piping. Using small pipe such as 1.5-inch size was very common when older pools were built. With the maximum water velocity of 8 feet per second required per today’s residential piping requirements, the maximum flow rate for a 1.5-inch pipe would be 50 gallons per minute (GPM). When considering the TDH loss of 1.5-inch piping, in many cases this is not enough flow to achieve proper turnover. Modern pool and spa combos typically require a minimum of 80 GPM to 100 GPM for sanitation. Pool builders should refer to PHTA-7 for additional information on achieving adequate flow and turnover rates on existing pool and spa systems.

4. EXCLUDING THE UNDERGROUND PIPING

When considering a renovation of the existing piping system for a pool or spa, replacing all piping with properly sized piping can be very expensive and may not be necessary. By replacing all piping above the ground, one can drastically reduce the system’s TDH Loss. Reducing the TDH increases the maximum flow of the system. One 2-inch, 90-degree elbow offers the resistance of 8.6 feet of 2-inch straight piping. If you reduce the number of these elbow fittings by five, you decrease the amount of TDH by 4.3 feet of head loss or 43 feet of piping. By using larger pipes, fittings and sweeps instead of elbows, you can make a major difference in the system’s flow resistance. This will help you attain the proper flow rates to maintain water quality and sanitation.

HOW TO DO IT

1. CALCULATE THE TOTAL SYSTEM TDH

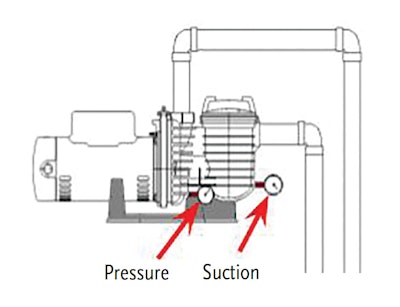

Before you start any work, you need to first determine the TDH Loss of the system. You can do this by installing a suction gauge on the suction side of the pump, a pressure gauge on the pressure side of the pump, and then operate the system at the maximum speed of the pump motor. Record the value on both gauges, multiply the pressure reading by 2.31 and the vacuum reading by 1.13, add the two values together, and this value will be the system TDH. Calculate the total volume of the pool in gallons, and then divide that amount by 720. The resulting value will be the flow you will need to turn over the pool in 12 hours. If you are dealing with a public pool, then divide by 360 and this will give you a six hour turnover rate. Equations for these calculations are shown below.

(PRESSURE (PSI) X 2.31) + (SUCTION (IN. Hg) X 1.13) = TDH

POOL VOLUME (GAL) ÷ 720 = 12-HOUR TURNOVER

POOL VOLUME (GAL) ÷ 360 = 6-HOUR TURNOVER

2. REPLACE THE ABOVEGROUND PIPING Evaluate the aboveground piping. Many older pools were installed by unqualified personnel. This usually means the existing system can be streamlined by eliminating unnecessary fittings, increasing the size of the piping, and using sweeps instead of standard elbows when possible. These improvements will drastically reduce the system’s TDH.

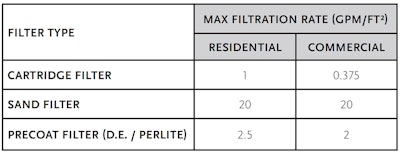

REPLACE THE FILTER

To achieve clean and clear water that will be properly sanitized, proper turnover flow rate is necessary. NSF/ANSI/CAN 50 Standard3 requires a maximum flow rate per square foot of filter size as illustrated in the table:

Using the pool system’s required turnover rate, you can easily determine the proper filter type and size. Having a properly sized filter will allow the pool circulation system to deliver clean, clear and properly sanitized pool water.

NOTE:

WHEN THE WORK IS COMPLETE

When you have completed your renovation, it is critical to verify the new maximum flow rate of your improved system. First, reinstall the pressure and vacuum gauges as described above. Operate your new pump at its maximum speed (3450 rpm). Record the gauge reading for both the suction and pressure. As mentioned before, multiply the pressure reading by 2.31 and the vacuum reading by 1.13, and then add the two values together. This value is the TDH Loss of your newly renovated system. Using the “pump curve” provided by the pump manufacturer, apply the TDH value to the pump curve. This will reveal the flow rate of your system at the maximum speed of the pump. Then check to see what the maximum flow rate of your suction outlet cover value is. The approved flow rate of your cover MUST BE EQUAL TO OR GREATER THAN the maximum flow rate of your system. In addition, the suction outlet cover must comply with ANSI/ASME A112.19.8, ANSI/APSP-16 2011 the Standard for Suction Fittings for Use in Swimming Pools, Wading Pools, Spas, and Hot Tubs; or its successor standard, ANSI/APSP/ ICC-16 2017, the Standard for Suction Outlet Fitting Assemblies (SOFA) for Use in Pools, Spas, and Hot Tubs.

VERIFY YOUR TURNOVER FLOW RATE

Leave the gauges in place as required to determine the maximum flow rate. Slow your pump by 500 rpm and obtain the reading from your gauges. As before, multiply the pressure gauge by 2.31 and the vacuum gauge by 1.13. Add the values and apply the TDH Loss to the pump curve — this will reveal a lower flow rate. Keep reducing the RPM of the pump until you can verify that you can provide the correct turnover flow rate of your pool. Keep in mind the turnover rate needed for smaller pools is often lower than the flow needed for proper skimmer, chlorinator and heater function. Set the filtration flow rate high enough for sanitation equipment to function properly.

WHY IS THIS IMPORTANT

By improving an existing pool or spa’s filtration system and improving the circulation, you will help ensure the pool and/ or spa maintains proper water quality and that it is safe to use. Waterborne diseases have continued to be an important issue in the pool space. The threat is real and must be taken seriously. In addition, water clarity (low turbidity) is critical for bather safety. If water clarity cannot be maintained due to poor system circulation, one may not be able to see a person who is at the bottom of the pool and in danger of drowning. Ensuring that the suction outlet covers are in compliance with the latest standard and code requirements is the final critical step in renovating an existing pool or spa, improving not only water quality, but safety as well.

REFERENCES

1. ANSI/PHTA/ICC-7 2020 American National Standard for Suction Entrapment Avoidance in Swimming Pools, Wading Pools, Spas, Hot Tubs and Catch Basins, Pool and Hot Tub Alliance, 2111 Eisenhower Ave., Suite 500, Alexandria, Virginia 22314, www.phta.org.

2. ANSI/APSP/ICC-16 2017 American National Standard for Suction Outlet Fitting Assemblies (SOFA) for Use in Pools, Spas and Hot Tubs, Pool and Hot Tub Alliance, 2111 Eisenhower Ave., Suite 500, Alexandria, Virginia 22314, www.phta.org.

3. NSF/ANSI/CAN 50 - 2020 Equipment and Chemicals for Swimming Pools, Spas, Hot Tubs, and Other Recreational Water Facilities.

The PHTA Recreational Water Quality Committee

Jody O’Grady, Taylor Technologies, Inc., Chair

Terry Arko, HASA, Inc.

Kevin Cox, NSF International

Dr. James Egan, LaMotte Company

Philip Escobedo, Fluidra

Rich Gallo, Pure Swim, Inc.

Kenneth Gregory, Pentair Water Quality Systems

Dr. Christopher M. Kareis, Axiall, A Westlake Company

Dr. Joseph Laurino, Periodic Products, PHTA Board of Directors Liaison

Touraj Rowhani, Sigura

Terry Snow, TLS Pool Service / Independent Pool and Spa Service Association (IPSSA) Representative

Dr. Roy Vore, Vore & Associates LLC

John Weber, BioLab, Inc.

Voting Alternates:

Jeff Gaulding, BioLab, Inc.

Ellen Meyer, Sigura

Consultants:

Jana Auringer, Pebble Technology International

Beth Hamil, MicroPlasma Ozone Technologies, Inc.

David Oxley, Pinellas Aquatic Consultation and Education

Dr. Stanley Pickens, Swim-Chem Consulting Services, LLC

This article first appeared in the March 2022 issue of AQUA Magazine — the top resource for retailers, builders and service pros in the pool and spa industry. Subscriptions to the print magazine are free to all industry professionals. Click here to subscribe.