Calcium Hypochlorite, a dry crystalline compound of chlorine, is a familiar sanitizer in the pool industry and has been a backbone of pool maintenance for many decades, but its unique features bear periodic examination as pool professionals continually reevaluate their sanitizing choices.

It is commercially available in dry mixtures containing up to 80% calcium hypochlorite, though 65 to 75% is more common and lower concentration formulations are also available.

High-strength calcium hypochlorite (≥ 65%) has been widely used as a disinfecting agent in swimming pools and municipal water treatment since 1928. It is a convenient source of available chlorine, one of the most widely used chemicals for disinfecting swimming pool water.

Sometimes called “cal hypo,” it is typically produced as hydrated (more than 5.5% water, but not more than 16% water) or anhydrous (less than 5.5% water). It is offered in various granular, tablet or briquette product forms labeled as an EPA-registered pesticide, for use in home, semi-private and commercial (public) pools. Formulations containing >20% water are also available.

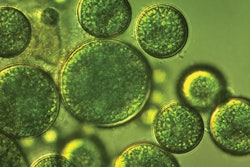

Calcium hypochlorite is soluble (18% or 1.5 lbs/gallon) in water, forming hypochlorous acid and hypochlorite ions, which are measured as free available chlorine (FAC). The relative amounts of hypochlorous acid and hypochlorite will depend on pH. Therefore, always maintain the pH between the recommended values of 7.2 and 7.8. The biocidal properties of calcium hypochlorite are due principally to hypochlorous acid, which kills bacteria, algae and other microorganisms. Hypochlorous acid is more effective as a biocide than hypochlorite ion. Because a residual level of FAC can be maintained with the use of calcium hypochlorite, it is classified as a primary sanitizer.

RELATED: Cal Hypo: The Facts

In addition to its use as a primary sanitizer, calcium hypochlorite can perform additional water treatment functions to control algae and to oxidize contaminants and chloramines. If the proper concentration of free chlorine (1.0 ppm to 4.0 ppm) is maintained in the pool with calcium hypochlorite, the swimming pool water will be properly sanitized, that is, the bacteria will be killed fast enough to control their populations in the pool water.

The free chlorine concentration for spas should be 2.0 to 5.0 ppm. The free chlorine generated from calcium hypochlorite helps provide clear water by killing algae and by destroying organic matter that will cloud the water if allowed to build up. Chloramines, the most common cause of unpleasant odors, are also eliminated by the action of free chlorine.

When calcium hypochlorite is used, 0.8 ppm of calcium hardness is added to the water for each ppm of available chlorine added. A certain amount of calcium hardness (usually within the range of 150 ppm to 1,000 ppm) is necessary to protect pool and spa surfaces and equipment from corrosion. However, if high amounts of hardness and alkalinity are present, high concentrations of calcium carbonate may result in scale formation or cloudy water. The first step in correcting this situation is to balance the water using the Langelier Saturation Index.

Ancillary products can be used to minimize scale formation and cloudy water. If additional measures are necessary, partially drain the pool and refill with fresh water where possible (providing the fill water has a lower calcium hardness level). Draining has the advantage of removing contaminants that have built up through use of the pool or spa. Draining is recommended as a periodic practice for all pools and spas to control the total dissolved solids.

APPLICATION

How calcium hypochlorite products are used depends upon the purpose of application and the product form. The EPA-registered product label will have explicit use instructions that describe how to apply the material for specific application purposes. Application methods will depend upon the product form being used and can range from broadcasting to skimmer feeding to the use of tablet feeders. Those requirements will be explained on each label.

The amount of product to be used or dispensed depends upon the specific application and the volume of water being treated. For example, in routine sanitizing use, the objective is to maintain a residual available chlorine (FAC) concentration of 1.0 ppm to 4.0 ppm for pools and 2.0 ppm to 5.0 ppm for spas. The label use instructions will explain how to determine a typical dosage for the water volume to be treated. Label use instructions will similarly define dosage requirements for other product applications such as oxidation, shock treatment or superchlorination.

RELATED: Pool Sanitizing: A Return to the Simple

The requirements for pool water testing in the application of calcium hypochlorite products should be indicated on the product label. The primary parameter to be tested is the level of FAC in the water. The choice of testing methods will vary depending on the type of pool (residential or commercial) and local regulations and standards. The product label should recommend that the pool water quality be properly balanced. This requires testing of the pool water balance parameters of pH, alkalinity, calcium hardness and stabilizer (i.e., cyanuric acid).

PRECAUTIONS

In order to safely use and handle calcium hypochlorite products, all individuals involved in their manufacture, distribution, sale and/or use should be trained and knowledgeable about their properties. Safety information is available on the product label, product Safety Data Sheet (SDS), and manufacturer’s training materials. This safety information will include product and packaging disposal instructions and spill response information.

Calcium hypochlorite is a dry solid with strong oxidizing properties. It is an oxidizing material because it readily yields oxygen or readily reacts to oxidize combustible materials. It is stable when stored in a cool, dry, ventilated area and not contaminated by other chemicals such as acids or easily oxidizable materials. Calcium hypochlorite, in the solid form, shall not be mixed with other pool chemicals including other chlorinating agents. Partially empty packages must not be consolidated, as this could result in dangerous mixing with incompatible dry chlorinating agents having a similar appearance.

As with any oxidizer, calcium hypochlorite can oxidize metals and may result in staining of pool and spa surfaces.

CAUTION: If mishandled, improperly stored or contaminated, calcium hypochlorite products can become unstable and dangerous, as is the case in general with chlorinating agents. Fire, explosion and/or release of toxic gasses could result, depending on the nature and amount of the contaminant.