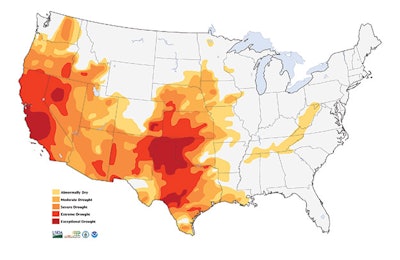

Our industry has suffered the impact of drought before, but in three crucial markets — California, Arizona and Texas — drought conditions have reached a new level of urgency for both government and the industry as a whole.

Government is concerned for obvious reasons, but the pool industry has about 40 percent of its annual inground market and its installed base wrapped up in these three states, and California alone accounts for roughly a third of U.S. spa sales.*

So the stakes are high. Orchestrating the response from the industry has been the California Pool and Spa Association and its drought education campaign, “Let’s Pool Together.” The CPSA has been working with other organizations such as the Association of California Water Agencies and the California Department of Water Resources to push water conservation measures in general and educate pool and spa owners and industry professionals about ways to maximize water efficiency.

As for the response from state government, the pool and spa industry has so far dodged crippling sanctions. On July 15, at the cost of a $500 fine, California’s state water board banned such activities as washing down driveways and watering of outdoor landscapes that cause excess runoff. The only restriction on the aquatic industry was to prohibit the use of potable water in fountains or water features unless the water is recirculated.

At the local level, it’s a different story. Many cities thus far have taken a non-binding, advisory role, encouraging citizens to reach an overall target water use reduction of 20 percent. Others, however, such as Santa Cruz, have taken a much tougher stance, with an outright ban on filling both pools and hot tubs, water rationing for every home, fines and mandatory “Water School” attendance for violators.

For the industry, the main concern is that if the rains don’t return, these kinds of draconian pronouncements will not be confined to outliers such as Santa Cruz, but will become the norm.

In the CPSA’s response to the drought, two important goals have emerged. The first is to redouble longstanding efforts to reduce water usage in the industry’s products. The second goal, at least as important, is to change the popular perception that pools and spas are major water wasters, and to impress popular opinion with an industry-wide effort to make every drop count.

There are many products and operational procedures that can affect water usage, and many of these are well understood. Most people are aware that a pool cover has a dramatic effect on evaporation rate, for instance. And it is common knowledge that keeping water balanced can extend its usable life, leaks in the plumbing will result in water loss, etc.

Perhaps less widely known are the effects of filtration methods on water usage. There is a dramatic difference in the amount of water consumed in the cleaning of D.E. and sand filters as opposed to cartridge filtration.

The disparity is caused by the need to backwash D.E. and sand filters — that is, to reverse the flow through the chamber to carry away debris down the drain or into the backyard, which results in a sizable amount of wasted water.

A few small calculations can quickly demonstrate the volumes involved. The amount of wasted water depends on the duration of the backwash, which depends on several factors, including the amount of debris in the filter and the habits of the serviceperson, but it can last anywhere from a minimum of one minute to as much as five minutes.

At 40 gpm, that five-minute backwash is 200 gallons. At 80 gpm, it’s 400 gallons. These amounts stand in contrast with the relatively small amount of water wasted when cartridge filters are cleaned.

Cartridge filters have no backwash valve at all. When cleaning these filters the cartridge is simply removed and sprayed off with a hose, which may require something on the order of 5 to 10 gallons, depending on how dirty it is.

(It’s worth noting that the absence of a backwash valve on a cartridge filter is a huge energy conservation feature as well. The valves that allow backwashing of sand and DE filters disrupt flow through those systems to the point where they add a significant amount of head to the pump.)

So per cleaning, backwashed filters use perhaps 10, 20 or 40 times the amount of water as non-backwashed (cartridge) filters. In absolute terms, the differential is in the hundreds of gallons.

To get an accurate comparison of the total wastewater differential between backwashed filters and cartridge filters, the frequency of cleaning must be considered, and this also varies so widely as to make such calculations fuzzy. There are homeowners who backwash their sand filters every week, others once a month or even twice a season. And conservation-minded manufacturers have done much to reduce the frequency of backwashing by increasing the size of filters (larger filters mean longer periods between cleaning) and by creating pre-filters that lengthen backwash periods by removing dirt before it gets to the filter.

Still, with minimum water savings in the hundreds of gallons per year and close to 2 million inground pools in California, Arizona and Texas*, a shift away from backwashed filtration would have a powerful effect on water usage in those drought-stricken states.

Just as important to the health of the aquatic industry is to be seen making changes to respond to the water crisis. Ultimately, public perception of the legitimacy of water vessels in a drought will determine their long-term prospects, and that will be informed in part by the industry’s water conservation efforts, even at the filtration level.

* PK Data research

Comments or thoughts on this article? Please e-mail [email protected].