Whether you’re a retailer, a builder or a service tech, you probably spend some time with filter media every day. Do you really know what’s in that bag? We thought we’d go back to school and take a look at the basics of filter media with an eye to new developments on the horizon.

Mr. Sandman

Sand is perhaps the simplest type of filter media. You may think that sand is sand, whether you’re walking on it at the beach or mixing it with Portland to pour a footing. But the sand that goes in the pool filter is a special kind, called industrial sand. It is composed mostly of quartz (also called crystalline silica) and is prized for its purity, inertness, hardness, resistance to high temperatures and grain size. Industrial sand deposits are less common than deposits mined for construction sand and gravel. Industrial sand is found in hard rock quartzite formations and in loose unconsolidated beds of silica sand. The United States produces 26 million tons of this commodity annually, but just a fraction is used in filtration.

Once the right kind of quartzite deposit is discovered, industrial sand production begins with mining. Some ore deposits are mined by scooping up loose material, some require blasting and crushing in quarries, and some are dredged from below the water table.

After the material is collected, it may be washed, processed to remove impurities, drained, dried and then screened to sort the material into different grades. In a pool system, sand filters the water by forming a network of spaces between the individual, irregularly shaped grains of sand. Anything larger than the spaces (typically about 10 to 12 microns) stays behind.

Silicon Bodies

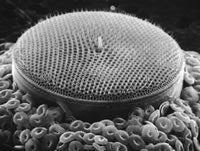

Diatomaceous earth is second in popularity to sand as a filter media. DE is also made of silica, but unlike industrial sand, it was once a living, aquatic organism called a diatom. “Melosira Granulata is one type of organism that becomes diatomaceous earth,” says Kimberly Walsh, a marketing director for EP Minerals, which supplies nearly all the DE used in the pool industry. “They live in water, when they die, they settle down to the bottom of the lake. At our mine outside of Reno, Nev., you can see how the deposits develop. You see a thick layer of white, that’s the diatomite, and after millions of years a volcano erupted or something and you see a dark layer of ash where the lake died off. Then the lake comes back to life again and the diatoms start to bloom again, and that’s represented in another layer of diatomaceous earth.

“The Reno bench represents about 13 million years of development, and I’m told that if we wait long enough, it will turn to oil,” she says. “The reason it’s still here for us to collect is it has a silica skeleton, which is very inert. Most skeletons are calcium based and don’t last.”

Walsh says the DE that’s available to the recreational water industry is just one type. “When you go out and buy DE now you have one choice, but for industrial uses we have many grades. For example we have a primary filtration grade and what we call a polish grade. You get a different clarity versus flow. As you get to these extremely small particle sizes you go to a lower flow, but extremely good clarity.” She says that in the past, DE was valued for its ability to produce very clear water, “We were never really looking at the health benefits before, Walsh says. “We just said, ‘Hey what grade of DE do we need to give you to get the clarity that you want?’”

But the recent attention on cryptosporidium outbreaks caused DE manufacturers to take another look. Walsh says a drinking-water study in the ’90s demonstrated that DE could remove 99.9 percent of the cryptosporisium in water samples. A study recently completed by James Amburgey of the University of North Carolina at Charlotte confirms the same efficacy for recreational water. “Right now the swimming pool industry is not using the fine grades of DE that are used in industrial applications,” says Walsh. “That’s something I’m changing. We are going to add a new version to give you the health benefits you get with the finer grades.”

Zeolite

Zeolite is often referred to as a molecular sieve. The microporous crystalline solids contain silicon, aluminum and oxygen. There are many different types of structures seen in zeolite. Many occur naturally as minerals, and are extensively mined in many parts of the world. Others are synthetic, and are made commercially for specific uses, or produced by research scientists trying to understand more about their chemistry. Because of their unique porous properties, zeolites are used in a variety of applications. Many detergents contain zeolite. Commercial wastewater contaminated with heavy metals, and nuclear effluent containing radioactive isotope can also be cleaned up using zeolite.

Perlite

Yet another siliceous material that makes an effective filter aid is perlite. It’s a naturally occurring volcanic rock that’s common throughout the world. Perlite’s water content is such that when it’s heated quickly to over 1,600 degrees Fahrenheit, it pops like popcorn and expands to about 20 times its unpopped volume. The particles have jagged, interlocking structures with microscopic channels that filter down to about 4 or 5 microns. Perlite is “popped” and full of tiny air pockets, so it’s very light. It can be manufactured to weigh as little as two pounds per cubic foot. Because it is a form of natural glass, it is classified as chemically inert.

Clear as Glass

A relative new kid on the filter block is yet another form of silica: recycled glass. Crushed, graded recycled glass has been used to replace sand in a growing number of commercial pools across the country, and is being seen in the residential market.

Crushed, recycled glass is equivalent to zeolite in its ability to reduce turbidity, according to manufacturers. It generally removes finer particles from water than silica sand of an equivalent grade. Crushed glass filtration media tends not to block or channel. The individual grains are amorphous and smooth and do not permanently trap bacteria in cracks.

According to TriVitro Corporation, a major supplier of the material, the glass can be used just as sand would be used in an ordinary sand filter. Glass lowers costs because it uses less water to backwash than sand does, and reduces the chemical demand, TriVitro says.

It Grows On Trees

Cellulose fiber is the principle structural material of plant-cell walls. The cellulose used in pool filters is processed and purified wood pulp and it is decidedly not made of silica. The fibers create a network that may filter down to 2 microns. Fans say that the non-abrasive fibers can weave themselves over small ruptures in filter elements. It can extend the filter cycle and is inert to acids, alkalis and solvents. It can be used alone or in combination with other filter media or added to a cartridge filter. One if its chief selling points is that it is biodegradable and non-toxic.